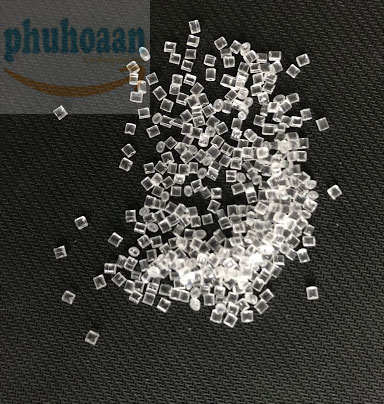

Hᚥt nháŧąa SAN 320HW

ThÃīng sáŧ káŧđ thuášt

Äáš·c Äiáŧm náŧi bášt cáŧ§a hᚥt nháŧąa SAN 350HW

Technical Data Sheet

Features: Super high strength, High heat resistance

Applications: Disposable lighter, Electric fan, Electronic parts

|

Physical |

Test Method |

Value |

|

Density |

ASTM D792 |

1.07 g/cm3 |

|

Melt Flow Index (230â, 3.8kg) (200â, 5.0kg) |

ASTM D1238 ASTM D1238 |

6.0 g/10min 1.4 g/10min |

|

Mold Shrinkage |

ASTM D955 |

0.2âž0.6 % |

|

Water absorption |

ASTM D570 |

0.3 % |

|

|

|

|

|

Mechanical |

Test Method |

Value |

|

Tensile Strength |

ASTM D638 |

810 kg/cm2 (11,502) (psi) |

|

Elongation |

ASTM D638 |

4.5 % |

|

Flexural Strength |

ASTM D790 |

1,100 kg/cm2 (15,620) (psi) |

|

Flexural Modulus |

ASTM D790 |

35,900 kg/cm2 (509,780) (psi) |

|

Izod Impact Strength(3.2mm) |

ASTM D256 |

1.5 kgcm/cm (0.28) (ft·lb/in) |

|

Rockwell Hardness(M scale) |

ASTM D785 |

86 |

|

|

|

|

|

Thermal |

Test Method |

Value |

|

Heat Deflection

Temperature(18.6kgf/cm2 ) |

ASTM D648 |

94 â (201) (â) |

|

Vicat Softening

Temperature(1kg, 50â/h) |

ASTM D1525 |

109 â (228) (â) |

|

|

|

|

|

Flammability |

Test Method |

Value |

|

Flame Rating - UL (1.6mm) |

UL 94 |

HB |

Processing guide

|

Injection Guide |

Unit |

Value |

|

Nozzle |

â |

190~220 |

|

Front |

â |

190~210 |

|

Middle |

â |

180~200 |

|

Rear |

â |

170~190 |

|

Hopper Throat |

â |

45 |

|

Mold |

â |

40~70 |

|

|

|

|

|

Drying |

Unit |

Value |

|

Temperature |

â |

75~85 |

|

Time |

hr |

2~4 |

Xem ảnh gốc

Xem ảnh gốc